Guaranteed Fitment

Always the correct part

have questions?

Always the correct part

We know our products

Fast & Reliable

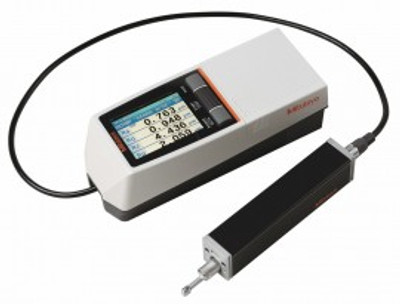

Providing both skidded and skidless measurements, this roughness tester has 46 roughness parameters that conform to ISO, DIN, ANSI, and JIS standards. Work with confidence with its high-resolution detector providing accurate measurements and features a high level of quality control. In addition, this roughness tester works with a digital filter function that delivers non-distorted roughness profiles and a limited contour analysis function that supports; step, level change, area, and coordinate difference measurements.

Features

Applications

| Measuring Range | X axis: 1" (25 mm)Z axis (detector): 800µm, 80µm, 8µm |

| Detector | Detection method: Differential inductanceResolution (range): 0.01 µm (800 µm) / 0.001 µm (80 µm) / 0.0001 µm (8 µm)Stylus tip shape (angle/radius): 90°/5 µmMeasuring force: 4 mNRadius of skid curvature: 1.57" (40 mm)Measuring methods: Skidless / skidded (switchable) |

| Drive Unit (X Axis) | Measuring speed: 0.002, 0.004, 0.02, 0.04" per second (0.05, 0.1, 0.2, 0.5, 1 mm/s)Drive speed: 0.02, 0.04, 0.08, 0.2" per second (0.5, 1, 2, 5 mm/s)Straightness: 0.3µm / 25 mm |

| Up/Down Inclination Unit | Vertical travel: 0.39" (10 mm)Inclination adjustment angle: ±1.5° |

| Applicable Standards | JIS 1982/JIS 1994/JIS 2001/ISO 1997/ANSI/VDA |

| Filter | 2CR, PC75, gaussianProfile: Primary profile, roughness profile, DF profile, waviness profile, roughness motif profile, waviness motif profile |

| Analysis Graph | Material ratio curve, profile height amplitude distribution curve |

| Data Compensation Functions | Parabola, hyperbola, ellipse, circle, tilt, no compensation |

| Cutoff Value | λc: 0.003, 0.01, 0.03, 0.1, 0.3" (0.08, 0.25, 0.8, 2.5, 8 mm)λs: 2.5, 8, 25µm |

| Calculation Display Unit | Customization: Selection of display/evaluation roughness parameterSimplified contour analysis function: Step, step quantity, area, coordinate differenceDAT (digimatic adjustment table) function: Helps to level workpiece prior to skidless measurementReal sampling function: Inputs the displacement of the detector while stopping the drive unitStatistical processing: Calculates the maximum value, minimum value, average value, standard deviation, pass rate and histogram for each parameterJudgment: Maximum value rule, 16% rule, mean value rule, standard deviation (1 σ, 2 σ, 3 σ)Storing measurement condition: Maximum 10 (calculation display unit)Print function (built-in thermal printer): Measurement condition/calculation result/Judgment result/calculation result per segment/tolerance value/evaluation curve/graphic curve/ material ratio curve/profile height amplitude distribution curve/environmental setting items/statistical result (Histogram)Display language: 16 languages (Japanese, English, German, French, Italian, Spanish, Portuguese, Korean, Chinese (simplified/traditional), Czech, Polish, Hungarian,Turkish, Swedish, Dutch)Storage function: Built-in memory; measurement condition (Up to 10)External I/O functions: USB I / F, digimatic output, RS-232C I / F, foot switch I / F |

| Power Supply | Built-in battery (rechargeable Ni-MH battery) /AC adapterCharging time of the built-in battery: about 4 hours (may vary due to ambient temperature)Endurance: About 1000 measurements (differs slightly due to use conditions /environment)Maximum power consumption: 50 W |

| Length | Sampling: 0.003, 0.01, 0.03, 0.1, 0.3, 1" (0.08, 0.25, 0.8, 2.5, 8, 25 mm)Arbitrary: 0.0039 to 1" (0.1 to 25 mm) |

| Dimensions | Calculation display unit: 10.83 x 7.8 x 4.29" (275 x 198 x 109 mm)Up /down inclination unit: 5.16 x 2.48 x 3.9" (131 x 63 x 99 mm)Drive unit: 5.04 x 1.41 x 1.83" (128 x 35.8 x 46.6 mm) |

| Weight | Calculation display unit: 3.7 lbs (1.7 kg)Up / down inclination unit: 0.88 lbs (0.4 kg)Drive unit: 1.3 lbs (0.6 kg) |

Everything you need to know about orders, cancellations, refunds, and delivery.

EquipTestPro ships to both Canada and the United States. We are pleased to serve customers across North America with reliable, trackable delivery options.

When you place an order, a flat-rate shipping charge will be applied at checkout based on your order. The applicable rate will be clearly displayed before you complete your purchase.

Flat-rate shipping is calculated to reflect the cost of reliable, insured delivery. The rate shown at checkout is final — no hidden surcharges will be added after your order is placed.

For certain items, shipping costs are calculated based on the weight of the product. The weight of any weight-based item is listed on its product detail page.

For example, an item weighing 3.2 lbs will be rated at 4 lbs for shipping calculation purposes. This policy is standard practice across all major carriers we work with.

Some products sold on EquipTestPro are subject to shipping restrictions due to regulatory, carrier, or safety requirements. These include but may not be limited to:

Where restrictions apply, this will be clearly noted on the product listing. If you have questions about a specific product's shipping eligibility to your location, please contact us before placing your order.

Orders are processed on business days (Monday through Friday, excluding statutory holidays). Orders placed after business hours or on weekends will begin processing the following business day.

You are entitled to cancel your Order within 30 days of receipt without providing a reason, subject to the processing fee structure described below.

The cancellation deadline is 30 days from the date on which you received the Goods, or on which a third party appointed by you (other than the carrier) takes possession of the delivered product.

To exercise your cancellation right, notify us with a clear written statement by:

The following fee structure applies to all cancellations. Please review carefully before requesting a cancellation.

A processing fee of 10% of the total order value will be withheld from your refund to cover payment processing, handling, and administrative costs.

If we cancel your order due to item unavailability, no processing fee will be withheld. You receive a full refund of the amount paid.

Refunds will be issued using the same payment method as the original purchase. No additional fees beyond those described above will be applied.

To be eligible for a return, all of the following conditions must be met:

We reserve the right to refuse returns of any merchandise that does not meet the above conditions, at our sole discretion.

The following items are not eligible for return under any circumstances:

You are responsible for the cost and risk of returning Goods to us. Before sending any items, please contact us at info@equiptestpro.com to obtain the return shipping address.

You should expect to receive your refund within four (4) weeks of delivering your return package to the shipper. In many cases, refunds are processed sooner. The timeline breaks down as follows:

We will process refunds no later than 14 days from the day we receive the returned Goods, using the same payment method as your original purchase.

If the Goods were marked as a gift at the time of purchase and shipped directly to you, a gift credit equal to the return value (less any applicable processing fee) will be issued. Once the returned product is received and inspected, a gift certificate will be mailed to you.

If the Goods were not marked as a gift at purchase, or if the gift giver had the order shipped to themselves first, the refund will be issued to the original purchaser.

Reach out to our support team for assistance with any order or return.

Not Applicable

| Condition: | NA |

Defective new equipment may be returned for warrantyrepair/exchange to us within (5) days of the shipment receipt date. After five (5) days, returns will be handled by direct contact and in accordance with the warranty terms of the item's manufacturer. Items that have malfunctioned due to mishandling, electrical overload, etc., will be subject to repair charge.

Non defective new equipment will be authorized for return within five (5) days of the shipment receipt date if the equipment is still in new, re-sellable condition with the original manual(s), accessories, packing material and carton. We reserve the right to reject returnsin which there is no original packaging, missing accessories, damage or visible signs of usage of the item. A restocking fee of up to 25% of purchase price may apply. Special orders and dangerous goods are non-returnable.

(Do not write anytingon the manufacturer's original package or use as a shipping carton. Include all accessories, manuals and warranties.)

Please, include a copy of the packing list or invoice with a reason for the return. Your return authorization number is valid for thirty (30) days.